Newhaven Stage 21: Fishing Jetty Update

Date published: August 15, 2025

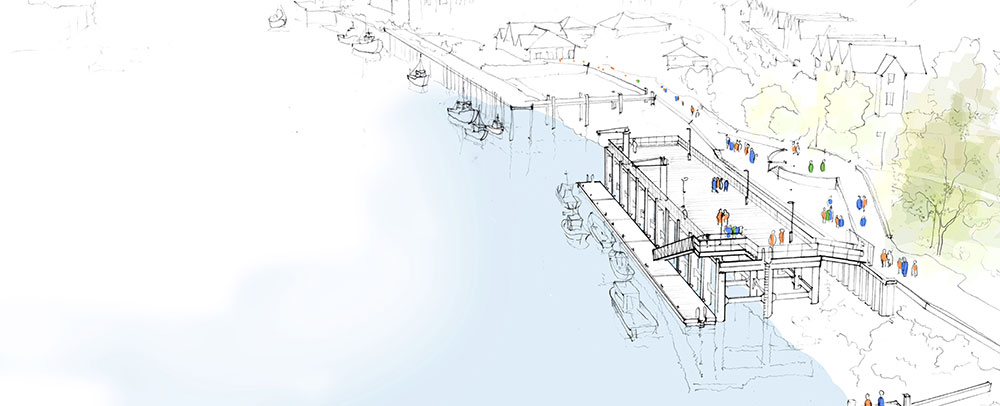

One of the most important phases of the Newhaven Fishing Stage 21 project is about to commence with the installation of new piles to form the river wall and fishing jetty structures. The project to replace fishing stages 10 & 11, with a new, modern fishing stage, complete with an access walkway and pontoon system, is being undertaken by Herbosch-Kiere Marine Contractors on behalf of Newhaven Port & Properties Ltd. The work is designed to enhance safety, usability, and efficiency for our hardworking local fishing community and to secure the future of Newhaven’s fishing industry.

The installation stage

The work will start by installing sheet piles to form the new river wall. This will replace the deteriorating existing wall, which also forms part of the local flood defences. Once in place, this new wall will provide improved protection against erosion and help safeguard nearby properties and businesses from flooding.

The contractors will then move on to the tubular support piles for the new fishing jetty. These large-diameter steel tubes are being delivered by sea from Wales and will provide the main structural supports for the jetty.

After this, the front combi-wall and sheet piled wing walls on either side of the new jetty will be completed, finalising the primary structure before moving into later phases of construction.

What are sheet piles, tubular piles, and a combi-wall?

- Sheet piles are long, interlocking steel sections driven into the ground to form a continuous wall. They are widely used in marine environments for riverbanks, quaysides, and flood defences because they provide strength, durability, and a watertight barrier.

- Tubular piles are large hollow steel tubes driven deep into the seabed to act as strong vertical supports for structures like jetties and piers. Their strength and stiffness make them ideal for carrying heavy loads such as cranes, vessels, and cargo.

- A combi-wall is a structure that combines tubular piles for main load-bearing strength with sheet piles placed between them to create a continuous wall. This method delivers both high structural capacity and an effective retaining or flood defence barrier.

How will piling be carried out?

The workers will be using a vibro hammer mounted on the crane aboard the jack-up barge Octopus. Unlike traditional impact hammers, this method vibrates the piles into the seabed, greatly reducing the sharp “bang” normally associated with piling. While there will still be some noise and vibration, it is much less intrusive than older methods.

Keeping noise and disturbance to a minimum

Our contractors know how important it is to keep disruption to a minimum and have put in place a number of measures to reduce the impact:

- Soft-start piling: The vibro hammer begins at reduced power for 20–30 seconds before increasing to full power.

- Noise monitoring: Real-time monitoring will alert the workers if they approach agreed noise limits, enabling them to take immediate action.

- Acoustic barriers: Noise-dampening panels have been installed on the landward side of our site fencing.

- Well-maintained plant: All machinery is fitted with effective silencers and kept in top condition to reduce unnecessary noise.

- Daily checks: Barriers and equipment inspection is undertaken daily to ensure all controls remain effective.

The importance of working with the community?

These new piles will form the backbone of a safer, more efficient fishing jetty, improve local flood defences, and provide modern infrastructure to support the fishing fleet for decades to come. This is a vital investment in Newhaven’s maritime future, and Newhaven Port & Properties Ltd want the community to feel proud of the result.

Read our earlier news item about the vessels.